Innovative ecological plastic packaging with a bright future!

Undoubtedly one of the most dominant trends in the packaging industry is the environmental friendliness. More and more businesses are turning to the use of ecological packaging in response to the concerns and demands of consumers worldwide on combating climate change and environmental pollution. In this context, a type of packaging that has received particular criticism for its impact on the ecosystem is the conventional plastic packaging because they are made from fossil fuels and are not easily recycled and thus pollute the environment irreparably. They have however evolved through certain technological and scientific processes which result in a smaller ecological footprint, thus making a difference both for the consumer and for the environment itself. Indeed, two-package categories which gain ever more popularity is the packaging of bioplastics and those made from waste / waste plastic collected from the sea.

Undoubtedly one of the most dominant trends in the packaging industry is the environmental friendliness. More and more businesses are turning to the use of ecological packaging in response to the concerns and demands of consumers worldwide on combating climate change and environmental pollution. In this context, a type of packaging that has received particular criticism for its impact on the ecosystem is the conventional plastic packaging because they are made from fossil fuels and are not easily recycled and thus pollute the environment irreparably. They have however evolved through certain technological and scientific processes which result in a smaller ecological footprint, thus making a difference both for the consumer and for the environment itself. Indeed, two-package categories which gain ever more popularity is the packaging of bioplastics and those made from waste / waste plastic collected from the sea.

These bioplastics, exhibit a number of functional characteristics which exceed those of conventional plastic packaging. Briefly:

These bioplastics, exhibit a number of functional characteristics which exceed those of conventional plastic packaging. Briefly:

– Protect the integrity of the product containing

– They are resistant to various temperatures, which is particularly important for products like food

– They help to increase the lifetime of the products on the shelf, contributing to reducing food waste

– They are made of renewable materials, contributing to reducing carbon dioxide emission into the atmosphere during production in order to have small ecological footprint

– They are light and produce small transport costs

– They can be adapted to be used for various applications (eg for cosmetics or for drinks and food) instead of conventional plastic, and is compatible with the production technologies of the last

– They can be reused and are recyclable

The main types of bioplastics are:

- Those made from biomass (i.e. from plants) and are non-biodegradable materials such as bio-polyethylene (Bio-PE) or bio-polyethylene terephthalate (Bio-PET) or polypropylene bio (Bio-PP)

- Those made from biomass and biodegradable-compostable as polylactic (PLA), polyhydroxyalkanoates (PHA), or various mixtures of starch (starch-based blends) or cellulose (cellulose)

- Minerals and biodegradable materials mainly mixed with the previous class of materials.

Indicatively, biopolymers and biodegradable bottles of 150ml and 500 ml made by 96% cane incorporating plastic colorful caps and a green logo to certify their environmental friendliness used by a British company for its products involving ecological shampoo, shower gels, oils and sprays -made of natural essential oils; for horses. The aim of this operation is to bring high quality and natural ingredients in its products, and to emphasize the eco ethos through the use of this type of packaging.

Indicatively, biopolymers and biodegradable bottles of 150ml and 500 ml made by 96% cane incorporating plastic colorful caps and a green logo to certify their environmental friendliness used by a British company for its products involving ecological shampoo, shower gels, oils and sprays -made of natural essential oils; for horses. The aim of this operation is to bring high quality and natural ingredients in its products, and to emphasize the eco ethos through the use of this type of packaging.

Similarly small cylindrical packaging tube shape made 100% from bioplastics namely bio-propylene derived from plant sources and are decorated with colors and graphic designs, used by Maltese cosmetics production company for lipstick, in order to offer consumers greener packaging for its products.

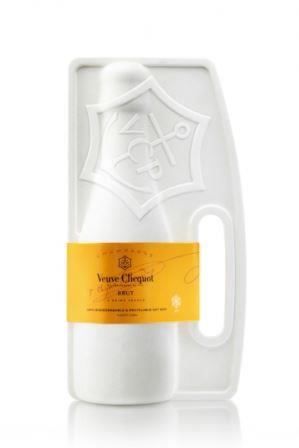

Furthermore, another innovative packaging is composed of biopolymer plastic made of industria lly processed starch derived from potatoes or cellulose fibers. It consists of two parts-such pieces joined together by a paper overwrap to form a handle. It also is able to keep the product fresh for up to two hours without refrigeration, it is easily transported, it is biodegradable and compostable. Such packaging was used as a gift box from a French champagne production company, aiming to provide a more durable and ecological solution to prospective buyers, and a pleasant shopping experience.

lly processed starch derived from potatoes or cellulose fibers. It consists of two parts-such pieces joined together by a paper overwrap to form a handle. It also is able to keep the product fresh for up to two hours without refrigeration, it is easily transported, it is biodegradable and compostable. Such packaging was used as a gift box from a French champagne production company, aiming to provide a more durable and ecological solution to prospective buyers, and a pleasant shopping experience.

Apart from the bioplastics that are gaining ground in the packaging industry and particularly in Europe, Asia, North and South America, another kind of innovative eco-plastic packaging has made its appearance and is also expected to employ in the future brands and consumers. This plastic packaging is made from plastic waste found in the oceans. The construction and use of such packages from various companies aims to sensitize consumers, while helping to combat ocean pollution.

Apart from the bioplastics that are gaining ground in the packaging industry and particularly in Europe, Asia, North and South America, another kind of innovative eco-plastic packaging has made its appearance and is also expected to employ in the future brands and consumers. This plastic packaging is made from plastic waste found in the oceans. The construction and use of such packages from various companies aims to sensitize consumers, while helping to combat ocean pollution.

A gray packaging used by an English company of cleaning products for the liquid cleaner was made by 10% of plastic recovered from the sea and 90% recycled high density polyethylene and from bioplastic derived from sugar cane. The company aims through this innovative solution to offer, inform and motivate potential buyers around the problem of ocean pollution and the need to take action to prevent the problem.

A gray packaging used by an English company of cleaning products for the liquid cleaner was made by 10% of plastic recovered from the sea and 90% recycled high density polyethylene and from bioplastic derived from sugar cane. The company aims through this innovative solution to offer, inform and motivate potential buyers around the problem of ocean pollution and the need to take action to prevent the problem.

Thus, both brands and consumers appear increasingly sensitive to environmental protection and choose packages with the less ecological footprint. Approximately one third of the US population over the age of 18 years often buy environmentally friendly products. As part of this trend are upgraded and plastic packaging to incorporate features that enhance the ecological profile, contributing simultaneously to solve major environmental issues. Such packages make a difference for both brands as well as for society and the environment and can reasonably be expected to employ us in the future.

References : www.en.european-bioplastics.org, Erin J. Wolford (2015), Ajay Kathuria (2015), Anne Marie Mohan (2014), Annie Kane (2014), Jennifer Elks (2012), Bob Sperber (2013), www.packagingeurope.com, www.packaging-gateway.com, www.bioplasticsmagazine.com, www.dkconsultants.gr.